Latest blogs

Created by - Elite Offshore

Maa Durga – A Divine Guide to Safety at Home and in Industries

Maa Durga – A Divine Guide to Safety at Home and in IndustriesMaa Durga, the goddess of power, courage, and protection, is worshipped across India as a symbol of victory over evil. Her ten arms, each holding a purposeful weapon, symbolize readiness, discipline, and the ability to protect those in her care. While her stories are deeply spiritual, her qualities are timeless lessons that can be applied to ensure safety both at home and in workplaces — especially in industries where lives depend on vigilance.Courage and PreparednessOne of Maa Durga’s greatest teachings is courage in the face of danger. In safety, this means not ignoring hazards but acting upon them. At home, it might be reporting a gas leak immediately; in industries, it means raising concerns about unsafe machinery or processes without fear. Just as Maa Durga’s weapons are always ready, safety equipment like fire extinguishers, first-aid kits, helmets, and harnesses should always be maintained and within reach.Discipline and VigilanceMaa Durga’s battles were won not only with strength but also through discipline and alertness. In safety, discipline means strictly following rules and procedures — wearing PPE, maintaining lockout-tagout systems, keeping escape routes clear, and attending safety training. Vigilance is about spotting small warning signs: a strange smell from the kitchen, a loose electrical wire, or an unusual sound from a machine. Many accidents happen because people get careless, but Maa Durga teaches us to stay watchful at all times.Using the Right ToolsEvery weapon in Maa Durga’s hands had a purpose, and she knew when and how to use it. In safety, choosing the right tool for the job is just as important. At home, this means using a stable ladder instead of a chair. In industries, it means wearing the correct gloves, helmets, and harnesses, and ensuring that tools and machinery are well maintained.Protection for AllMaa Durga fights not for herself but for the well-being of all. Safety too is not just about self-protection — it is about protecting others. At home, this includes keeping hazardous substances away from children or helping elders avoid tripping hazards. In the workplace, it means looking out for co-workers, ensuring they follow safety measures, and lending a hand during emergencies.Environmental SafetyOne form of Maa Durga, Maa Shailputri, represents harmony with nature. True safety is not limited to people — it also includes safeguarding the environment. This means preventing oil spills, reducing pollution, managing industrial waste responsibly, and handling chemicals with care.Defeating the Demons of NegligenceThe demons Maa Durga fought can be compared to modern-day threats like negligence, ignorance, and overconfidence. Just as she never underestimated Mahishasura, we must never underestimate risks. A worker skipping a helmet “just for a minute” or a homeowner ignoring a faulty gas regulator invites danger. Small acts of negligence can lead to major disasters.Safety as a Team EffortMaa Durga’s victory was possible because the gods came together to empower her. In the same way, safety is a collective responsibility. Every worker, supervisor, and manager must work together to remove hazards and build a culture of protection.ConclusionWhen we see Maa Durga during Navratri, we can view her as the ultimate safety officer — courageous, disciplined, alert, protective, and prepared. By practicing her values in our homes and industries, we not only honor her in prayer but also in action. Her divine lessons remind us that safety is not just a rule, but a way of life — ensuring that everyone returns home safe, every single day.

More detailsPublished - Thu, 14 Aug 2025

Created by - Elite Offshore

The Alarming Decline in Safety and Skill Training: A Risk We Can't Ignore

Safety and skill training are the backbone of industrial and workplace efficiency. They ensure that workers are competent, prepared, and safe while carrying out their tasks. Yet, mostly in the developing and underdeveloped regions, the decline in the seriousness given to safety and skill training is a worrying trend that threatens lives, livelihoods, and the very foundation of sustainable development.Why Safety and Skill Training MatterWorkplace safety is more than just a compliance checklist; it is a commitment to protect lives. Whether it is a factory floor, a construction site, or an offshore rig, proper safety measures can prevent accidents, injuries, and fatalities. Similarly, skill training equips workers with the knowledge and expertise to perform their jobs efficiently and innovate in their roles. Together, they create a competent workforce that can drive industrial growth without compromising safety.In countries like India and across much of the developing world, the demand for skilled labour is immense. These regions are rapidly industrialising, and projects in construction, manufacturing, and oil and gas sectors are growing. Yet, the quality and availability of training in safety and skills have not kept pace with this growth. The consequences of this neglect are both immediate and far-reaching.The Alarming Trends1. Cutting Corners to Save CostsIn many industries, safety and skill training are viewed as unnecessary expenditures rather than investments. Employers, especially smaller companies, often cut corners to save money, providing minimal or no training to their workers. The mindset of "just get the job done" takes precedence over ensuring safety, leading to untrained workers being put in hazardous situations.2. Lack of AwarenessA significant factor behind the decline is a lack of awareness about the importance of safety and skill training. Workers are often unaware of their rights to proper training and safe working conditions. Employers, on the other hand, fail to realize that investing in training reduces long-term costs associated with accidents, downtime, and poor productivity.3. Outdated Training MethodsWhere training does exist, it is often outdated or irrelevant to modern industrial practices. Many training programs rely on theoretical lectures without practical applications, leaving workers ill-prepared for real-world challenges. The absence of proper practical training infrastructure, as available with Elite Offshore, and advanced tools such as virtual reality (VR) simulations, hands-on drills, and updated materials further diminishes the quality of training.4. Unregulated IndustriesIn third world countries, a significant portion of the workforce is employed in unorganized or semi-regulated sectors. These industries often operate outside strict regulatory frameworks, leaving workers vulnerable to unsafe conditions. In such environments, safety and skill training are rarely prioritized.5. Overlooking Soft SkillsSkill training often focuses solely on technical capabilities, neglecting critical soft skills such as communication, teamwork, and problem-solving. This narrow approach limits workers' ability to adapt to dynamic environments, handle emergencies, and work collaboratively.The Consequences of Neglect1. Rising Workplace AccidentsThe most tragic outcome of declining safety training is an increase in workplace accidents. The International Labour Organization (ILO) estimates that approximately 2.3 million people die annually from work-related accidents and diseases globally. Developing countries bear a disproportionate share of this burden.2. Economic LossesAccidents and inefficiencies caused by a lack of training lead to significant economic losses. Medical costs, compensation, downtime, and damaged equipment all add up. For small businesses, these costs can be crippling.3. Poor ProductivityA workforce that lacks proper skills cannot perform at its full potential. Poor productivity leads to lower quality products, missed deadlines, and dissatisfied clients, further impacting economic growth.4. Loss of Global CompetitivenessIn a globalised world, industries in developing countries must compete with those in more advanced economies. Without a skilled and safety-conscious workforce, businesses in these regions struggle to meet international standards, losing out on lucrative opportunities.5. Human SufferingBeyond numbers and statistics, the human cost of neglecting safety and skill training is immeasurable. Families lose breadwinners, and workers face lifelong disabilities due to preventable accidents. The emotional toll on communities is profound.The Way ForwardAddressing the decline in safety and skill training requires a collective effort from governments, industries, educational institutions, and society at large. Here are some steps to reverse the trend:1. Stronger Regulations and EnforcementGovernments must enforce stringent safety standards and ensure compliance through regular inspections. Penalties for non-compliance should be severe enough to discourage negligence.2. Public-Private PartnershipsIndustries and governments can collaborate to create training programs that meet specific sectoral needs. Initiatives like India's Skill India campaign can be scaled up to include robust safety components with private sector encouraged to contribute to such training with support from government.3. Modernizing Training MethodsTraining programs must embrace simulating real scenarios. Modern tools such as VR, augmented reality (AR), and e-learning platforms may be productive add ons. These technologies make training more engaging, practical, and accessible.4. Awareness CampaignsRaising awareness among workers about their rights and the importance of safety training is crucial. Employers must also be educated about the long-term benefits of investing in a trained workforce.5. Certification and AccreditationImplementing mandatory certifications for workers and employers can ensure that only trained personnel handle critical operations. Accredited or approved training centers should be established to maintain consistent quality.6. Incentivizing ComplianceGovernments can provide tax benefits or subsidies to companies that prioritize safety and skill training. Recognizing and rewarding such companies publicly can further encourage others to follow suit.7. Incorporating Soft SkillsTraining programs should include modules on soft skills, enabling workers to function effectively in diverse teams and adapt to changing workplace demands.Thus the decline in safety and skill training in the Indian subcontinent and other developing regions is a ticking time bomb. It not only endangers lives but also stunts economic growth and progress. The solution lies in treating safety and skill training as non-negotiable investments rather than optional expenditures. With collective willpower and a commitment to change, we can build a future where workplaces are safe, workers are skilled, and industries thrive.Ignoring this issue is no longer an option. The time to act is now.

More detailsPublished - Fri, 27 Dec 2024

Created by - Elite Offshore

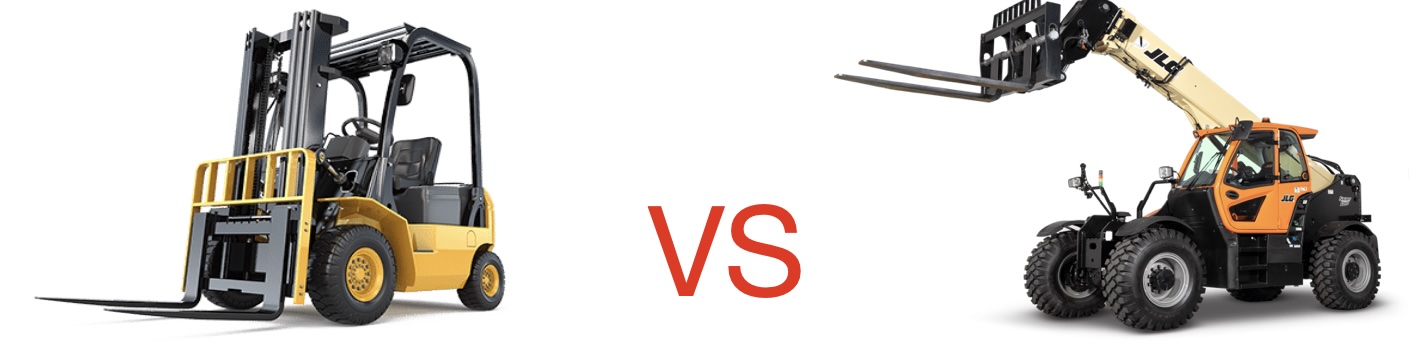

Telescopic Handlers (Telehandlers) vs Rough Terrain Forklifts

Telescopic handlers (telehandlers) and Rough terrain forklifts are both designed for heavy lifting in outdoor environments, but they serve slightly different purposes and have key structural differences. A comparison given below: A Telescopic Handler (Telehandler) A Rough Terrain Forklift1. Design and StructureA telehandler has an extendable telescoping boom that can reach both horizontally and vertically, much like a crane. This makes it more versatile for accessing elevated or hard-to-reach places. At the end of the boom, various attachments can be fitted, such as pallet forks, buckets, or work platforms.A Rough Terrain Forklift has a traditional mast and forks like standard forklifts but is equipped with large tires, heavy-duty suspension, and a reinforced frame to handle rough outdoor surfaces. It lifts vertically with a standard fork but lacks the telescoping boom.2. Lifting and Reach CapabilityThe extendable boom of telehandler allows it to lift loads to significant heights and reach forward across obstacles, making it useful for construction sites where materials need to be placed in elevated or otherwise inaccessible locations.The Rough Terrain Forklift can lift heavy loads and operate on uneven terrain, its reach is limited to vertical lifting. It cannot extend horizontally, so it’s typically used where loads need to be lifted and moved over shorter distances without height requirements.3. Versatility and AttachmentsTelehandlers are extremely versatile due to its range of compatible attachments, such as grapples, buckets, or winches, making it adaptable for various jobs.Rough Terrain Forklifts are primarily used for lifting and transporting palletized materials on rough ground. It’s generally limited to forks, though some models offer limited attachment options.4. Stability and ManeuverabilityTelehandlers are designed for stability, especially when using extended reaches. It often has outriggers or stabilizers to maintain balance when lifting heavy loads at high angles.Rough Terrain Forklifts typically are more compact and easier to maneuver in tighter spaces. Its heavy-duty tires and suspension are specifically designed for handling uneven ground without additional stabilizers, making it ideal for construction sites with limited space.5. Typical UsesTelehandlers are preferred for construction sites where materials need to be placed at height or moved across obstacles. It’s also popular in agriculture for stacking hay bales or loading materials.Rough Terrain Forklifts are commonly used in outdoor material handling and warehousing, especially in settings like lumber yards, stone yards, or agricultural sites where ground conditions are rough but loads don’t need to be lifted high or across obstacles.Thus while both are built for tough terrain, a telehandler is better for versatile lifting and reaching tasks, whereas a rough terrain forklift is ideal for lifting loads vertically and transporting them over uneven ground in tighter spaces.

More detailsPublished - Thu, 31 Oct 2024

Created by - Elite Offshore

Enhancing Safety, Health, and Environmental Protection through Training

Human factors play a vital role in the safety, health, and environmental (HSE) performance of any organization. These factors refer to how people interact with their work environment, tasks, equipment, and procedures, and how these interactions influence overall safety and health. In high-risk industries such as oil and gas, manufacturing, construction, and maritime, paying attention to human factors through effective training can greatly improve HSE performance.A major area where human factors impact HSE is safety. Many workplace accidents occur due to human errors like poor judgment, lack of attention, or bad decisions. These mistakes are often preventable with proper training. Training programs that focus on identifying hazards, understanding safety procedures, and using equipment correctly help employees become more aware of risks. When workers are trained to recognize dangers and respond safely in critical situations, the chances of accidents and injuries drop significantly.Behavior-Based Safety (BBS) training is a powerful method to improve safety at work. It encourages safe behaviors and discourages risky actions by helping employees become aware of their unsafe habits. Through BBS training, workers can make positive changes in their behavior, which leads to fewer accidents and creates a strong safety-first culture within the organization. As a result, the overall health and safety standards of the workplace improve.Health is another important factor in HSE performance. In many industries, workers face health risks from exposure to hazardous materials, heavy machinery, or extreme working conditions. Training that focuses on health awareness can help employees protect themselves. For example, they can learn how to use personal protective equipment (PPE) properly, follow ergonomic practices to avoid injury, and understand the importance of regular health check-ups. A workforce that is healthy is more productive and less likely to experience workplace injuries or long-term illnesses.Environmental protection is also closely tied to human factors. Many industries have a direct impact on the environment, and employee behavior can make a big difference in how well an organization manages its environmental responsibilities. Training workers to follow environmental protection guidelines, such as proper waste management, pollution control, and resource conservation, can reduce harmful practices. When employees are aware of the environmental impact of their actions, they are more likely to make decisions that support sustainability, helping to reduce the company’s environmental footprint.Training is key to addressing human factors in HSE performance. It not only gives workers the knowledge and skills they need but also helps create a safety-first mindset throughout the organization. The best training programs combine both theory and hands-on exercises. For example, drills that simulate real-life situations like emergency evacuations, firefighting, and chemical spill responses allow employees to practice their skills in a controlled environment. This boosts their confidence and ensures they are prepared to act correctly in actual emergencies.Another benefit of focusing on human factors in HSE through training is improved teamwork and communication. In high-risk workplaces, good communication and teamwork are essential for preventing accidents. Training that emphasizes leadership, cooperation, and clear communication helps everyone work together toward shared safety and environmental goals.In conclusion, human factors are critical to improving HSE performance. By addressing safety, health, and environmental protection through targeted training, organizations can reduce accidents, improve worker well-being, and contribute to a safer, more sustainable environment.

More detailsPublished - Fri, 27 Sep 2024

Created by - Elite Offshore

Career Progression and Opportunities in the Rigging Profession

The career of a RIGGER is both challenging and rewarding, requiring a combination of physical skill, technical knowledge, and a strong understanding of safety protocols. Rigging involves the safe handling, movement, and securing of heavy loads using various types of equipment such as cranes, hoists, and slings. The progression in this field typically follows a path from Rigger Level 1 to Rigger Level 4, with each stage involving increasingly complex tasks and responsibilities.Rigger Level 1: Starting the JourneyA Rigger Level 1 is often an entry-level position where individuals learn the basics of rigging. This stage focuses on simple, repetitive tasks, such as attaching rigging equipment, selecting appropriate rigging methods, and ensuring that all rigging setups are secure. At this level, the rigger works under supervision and deals with known load weights and configurations. The primary skills developed include inspecting rigging before use, identifying and selecting rigging components, and recognizing potential hazards in the rigging process. This stage is critical for building a solid foundation in rigging practices and safety standards.Rigger Level 4: Advancing in the FieldAs a rigger gains experience and confidence, they can progress to Rigger Level 4. This level allows for more independence and involves more complex rigging tasks, such as calculating load weights, determining the center of gravity, and selecting appropriate rigging components for specific jobs. A Rigger Level 4 can perform these tasks without supervision and is expected to have a deep understanding of load dynamics, hoisting equipment, and the various factors that can affect the stability and safety of a lift. This level of certification also includes performing pre-use inspections of rigging equipment and identifying lift points, which are crucial for ensuring safe and efficient operations.Career Opportunities and ProgressionRiggers have opportunities across various industries, including construction, oil and gas, manufacturing, shipping, and even the entertainment industry. The skills developed as a rigger are highly transferable, allowing individuals to move between different sectors. For example, construction riggers may transition into crane operation or specialize in specific rigging tasks like heavy lifting in offshore oil rigs.The progression from Rigger Level 1 to Level 4 not only increases job responsibilities but also opens up avenues for higher wages and specialized roles. Certification, often provided by recognized bodies like the API and National Commission for the Certification of Crane Operators (NCCCO), is crucial in advancing a rigger's career, as it demonstrates competence and adherence to safety standards. With experience and further training, riggers can advance to supervisory roles or specialize in more technical areas of rigging, such as crane operation or lift planning.In summary, a career as a rigger offers a structured path of progression with opportunities for specialization and advancement in various industries. The key to success in this field is continuous learning, hands-on experience, and a commitment to safety and precision in every task. For more detailed information on becoming a certified rigger and the specific tasks involved at each certification level, you can explore resources like the [NCCCO](https://www.nccco.org/) and specialized training providers like [Elite Offshore](https://eliteoffshore.in).

More detailsPublished - Sat, 31 Aug 2024

Created by - Elite Offshore

Role of Safety Signs in Promoting a Safer Work Environment

Safety signs play an important role in maintaining a safe and organized work environment. They communicate potential hazards and risks to employees and visitors and alert individuals to dangers such as slippery floors, electrical hazards, chemical exposures, or restricted areas. They serve as constant reminders about safe practices and procedures. Safety signs provide clear instructions on what actions to take to maintain safety. For example, they may indicate the location of emergency exits, first aid kits, fire extinguishers, or safety equipment. They contribute to creating a safer environment for everyone.During any emergencies, safety signs provide critical information quickly. They guide individuals to safety exits and emergency equipment, ensuring a prompt and organized response to crises like fires, chemical spills, or medical emergencies. In diverse workplaces, safety signs use universally recognized symbols and icons to overcome language barriers. This ensures that safety information is understood by all employees, regardless of their native language.Safety signs may be categorised as below:1. Warning signs 2. Prohibition signs 3. Emergency signs4. Hazard signs5. Road safety signs 6. Fire Safety Signs7. Construction safety signs8. Safety awareness signs9. Commercial floor signs10. Braille signsThus Safety signs play a crucial role and are integral to promoting a safety-conscious culture, preventing accidents, complying with regulations, and ensuring everyone in the workplace understands and follows essential safety protocols. These topics are adequately covered during various safety training programs e.g. Workplace Safety.

More detailsPublished - Thu, 18 Jul 2024

Popular blogs

Created by - Elite Offshore

The Alarming Decline in Safety and Skill Training: A Risk We Can't Ignore

Safety and skill training are the backbone of industrial and workplace efficiency. They ensure that workers are competent, prepared, and safe while carrying out their tasks. Yet, mostly in the developing and underdeveloped regions, the decline in the seriousness given to safety and skill training is a worrying trend that threatens lives, livelihoods, and the very foundation of sustainable development.Why Safety and Skill Training MatterWorkplace safety is more than just a compliance checklist; it is a commitment to protect lives. Whether it is a factory floor, a construction site, or an offshore rig, proper safety measures can prevent accidents, injuries, and fatalities. Similarly, skill training equips workers with the knowledge and expertise to perform their jobs efficiently and innovate in their roles. Together, they create a competent workforce that can drive industrial growth without compromising safety.In countries like India and across much of the developing world, the demand for skilled labour is immense. These regions are rapidly industrialising, and projects in construction, manufacturing, and oil and gas sectors are growing. Yet, the quality and availability of training in safety and skills have not kept pace with this growth. The consequences of this neglect are both immediate and far-reaching.The Alarming Trends1. Cutting Corners to Save CostsIn many industries, safety and skill training are viewed as unnecessary expenditures rather than investments. Employers, especially smaller companies, often cut corners to save money, providing minimal or no training to their workers. The mindset of "just get the job done" takes precedence over ensuring safety, leading to untrained workers being put in hazardous situations.2. Lack of AwarenessA significant factor behind the decline is a lack of awareness about the importance of safety and skill training. Workers are often unaware of their rights to proper training and safe working conditions. Employers, on the other hand, fail to realize that investing in training reduces long-term costs associated with accidents, downtime, and poor productivity.3. Outdated Training MethodsWhere training does exist, it is often outdated or irrelevant to modern industrial practices. Many training programs rely on theoretical lectures without practical applications, leaving workers ill-prepared for real-world challenges. The absence of proper practical training infrastructure, as available with Elite Offshore, and advanced tools such as virtual reality (VR) simulations, hands-on drills, and updated materials further diminishes the quality of training.4. Unregulated IndustriesIn third world countries, a significant portion of the workforce is employed in unorganized or semi-regulated sectors. These industries often operate outside strict regulatory frameworks, leaving workers vulnerable to unsafe conditions. In such environments, safety and skill training are rarely prioritized.5. Overlooking Soft SkillsSkill training often focuses solely on technical capabilities, neglecting critical soft skills such as communication, teamwork, and problem-solving. This narrow approach limits workers' ability to adapt to dynamic environments, handle emergencies, and work collaboratively.The Consequences of Neglect1. Rising Workplace AccidentsThe most tragic outcome of declining safety training is an increase in workplace accidents. The International Labour Organization (ILO) estimates that approximately 2.3 million people die annually from work-related accidents and diseases globally. Developing countries bear a disproportionate share of this burden.2. Economic LossesAccidents and inefficiencies caused by a lack of training lead to significant economic losses. Medical costs, compensation, downtime, and damaged equipment all add up. For small businesses, these costs can be crippling.3. Poor ProductivityA workforce that lacks proper skills cannot perform at its full potential. Poor productivity leads to lower quality products, missed deadlines, and dissatisfied clients, further impacting economic growth.4. Loss of Global CompetitivenessIn a globalised world, industries in developing countries must compete with those in more advanced economies. Without a skilled and safety-conscious workforce, businesses in these regions struggle to meet international standards, losing out on lucrative opportunities.5. Human SufferingBeyond numbers and statistics, the human cost of neglecting safety and skill training is immeasurable. Families lose breadwinners, and workers face lifelong disabilities due to preventable accidents. The emotional toll on communities is profound.The Way ForwardAddressing the decline in safety and skill training requires a collective effort from governments, industries, educational institutions, and society at large. Here are some steps to reverse the trend:1. Stronger Regulations and EnforcementGovernments must enforce stringent safety standards and ensure compliance through regular inspections. Penalties for non-compliance should be severe enough to discourage negligence.2. Public-Private PartnershipsIndustries and governments can collaborate to create training programs that meet specific sectoral needs. Initiatives like India's Skill India campaign can be scaled up to include robust safety components with private sector encouraged to contribute to such training with support from government.3. Modernizing Training MethodsTraining programs must embrace simulating real scenarios. Modern tools such as VR, augmented reality (AR), and e-learning platforms may be productive add ons. These technologies make training more engaging, practical, and accessible.4. Awareness CampaignsRaising awareness among workers about their rights and the importance of safety training is crucial. Employers must also be educated about the long-term benefits of investing in a trained workforce.5. Certification and AccreditationImplementing mandatory certifications for workers and employers can ensure that only trained personnel handle critical operations. Accredited or approved training centers should be established to maintain consistent quality.6. Incentivizing ComplianceGovernments can provide tax benefits or subsidies to companies that prioritize safety and skill training. Recognizing and rewarding such companies publicly can further encourage others to follow suit.7. Incorporating Soft SkillsTraining programs should include modules on soft skills, enabling workers to function effectively in diverse teams and adapt to changing workplace demands.Thus the decline in safety and skill training in the Indian subcontinent and other developing regions is a ticking time bomb. It not only endangers lives but also stunts economic growth and progress. The solution lies in treating safety and skill training as non-negotiable investments rather than optional expenditures. With collective willpower and a commitment to change, we can build a future where workplaces are safe, workers are skilled, and industries thrive.Ignoring this issue is no longer an option. The time to act is now.

More detailsPublished - Fri, 27 Dec 2024

Created by - Elite Offshore

Telescopic Handlers (Telehandlers) vs Rough Terrain Forklifts

Telescopic handlers (telehandlers) and Rough terrain forklifts are both designed for heavy lifting in outdoor environments, but they serve slightly different purposes and have key structural differences. A comparison given below: A Telescopic Handler (Telehandler) A Rough Terrain Forklift1. Design and StructureA telehandler has an extendable telescoping boom that can reach both horizontally and vertically, much like a crane. This makes it more versatile for accessing elevated or hard-to-reach places. At the end of the boom, various attachments can be fitted, such as pallet forks, buckets, or work platforms.A Rough Terrain Forklift has a traditional mast and forks like standard forklifts but is equipped with large tires, heavy-duty suspension, and a reinforced frame to handle rough outdoor surfaces. It lifts vertically with a standard fork but lacks the telescoping boom.2. Lifting and Reach CapabilityThe extendable boom of telehandler allows it to lift loads to significant heights and reach forward across obstacles, making it useful for construction sites where materials need to be placed in elevated or otherwise inaccessible locations.The Rough Terrain Forklift can lift heavy loads and operate on uneven terrain, its reach is limited to vertical lifting. It cannot extend horizontally, so it’s typically used where loads need to be lifted and moved over shorter distances without height requirements.3. Versatility and AttachmentsTelehandlers are extremely versatile due to its range of compatible attachments, such as grapples, buckets, or winches, making it adaptable for various jobs.Rough Terrain Forklifts are primarily used for lifting and transporting palletized materials on rough ground. It’s generally limited to forks, though some models offer limited attachment options.4. Stability and ManeuverabilityTelehandlers are designed for stability, especially when using extended reaches. It often has outriggers or stabilizers to maintain balance when lifting heavy loads at high angles.Rough Terrain Forklifts typically are more compact and easier to maneuver in tighter spaces. Its heavy-duty tires and suspension are specifically designed for handling uneven ground without additional stabilizers, making it ideal for construction sites with limited space.5. Typical UsesTelehandlers are preferred for construction sites where materials need to be placed at height or moved across obstacles. It’s also popular in agriculture for stacking hay bales or loading materials.Rough Terrain Forklifts are commonly used in outdoor material handling and warehousing, especially in settings like lumber yards, stone yards, or agricultural sites where ground conditions are rough but loads don’t need to be lifted high or across obstacles.Thus while both are built for tough terrain, a telehandler is better for versatile lifting and reaching tasks, whereas a rough terrain forklift is ideal for lifting loads vertically and transporting them over uneven ground in tighter spaces.

More detailsPublished - Thu, 31 Oct 2024

Created by - Elite Offshore

Enhancing Safety, Health, and Environmental Protection through Training

Human factors play a vital role in the safety, health, and environmental (HSE) performance of any organization. These factors refer to how people interact with their work environment, tasks, equipment, and procedures, and how these interactions influence overall safety and health. In high-risk industries such as oil and gas, manufacturing, construction, and maritime, paying attention to human factors through effective training can greatly improve HSE performance.A major area where human factors impact HSE is safety. Many workplace accidents occur due to human errors like poor judgment, lack of attention, or bad decisions. These mistakes are often preventable with proper training. Training programs that focus on identifying hazards, understanding safety procedures, and using equipment correctly help employees become more aware of risks. When workers are trained to recognize dangers and respond safely in critical situations, the chances of accidents and injuries drop significantly.Behavior-Based Safety (BBS) training is a powerful method to improve safety at work. It encourages safe behaviors and discourages risky actions by helping employees become aware of their unsafe habits. Through BBS training, workers can make positive changes in their behavior, which leads to fewer accidents and creates a strong safety-first culture within the organization. As a result, the overall health and safety standards of the workplace improve.Health is another important factor in HSE performance. In many industries, workers face health risks from exposure to hazardous materials, heavy machinery, or extreme working conditions. Training that focuses on health awareness can help employees protect themselves. For example, they can learn how to use personal protective equipment (PPE) properly, follow ergonomic practices to avoid injury, and understand the importance of regular health check-ups. A workforce that is healthy is more productive and less likely to experience workplace injuries or long-term illnesses.Environmental protection is also closely tied to human factors. Many industries have a direct impact on the environment, and employee behavior can make a big difference in how well an organization manages its environmental responsibilities. Training workers to follow environmental protection guidelines, such as proper waste management, pollution control, and resource conservation, can reduce harmful practices. When employees are aware of the environmental impact of their actions, they are more likely to make decisions that support sustainability, helping to reduce the company’s environmental footprint.Training is key to addressing human factors in HSE performance. It not only gives workers the knowledge and skills they need but also helps create a safety-first mindset throughout the organization. The best training programs combine both theory and hands-on exercises. For example, drills that simulate real-life situations like emergency evacuations, firefighting, and chemical spill responses allow employees to practice their skills in a controlled environment. This boosts their confidence and ensures they are prepared to act correctly in actual emergencies.Another benefit of focusing on human factors in HSE through training is improved teamwork and communication. In high-risk workplaces, good communication and teamwork are essential for preventing accidents. Training that emphasizes leadership, cooperation, and clear communication helps everyone work together toward shared safety and environmental goals.In conclusion, human factors are critical to improving HSE performance. By addressing safety, health, and environmental protection through targeted training, organizations can reduce accidents, improve worker well-being, and contribute to a safer, more sustainable environment.

More detailsPublished - Fri, 27 Sep 2024

Created by - Elite Offshore

Career Progression and Opportunities in the Rigging Profession

The career of a RIGGER is both challenging and rewarding, requiring a combination of physical skill, technical knowledge, and a strong understanding of safety protocols. Rigging involves the safe handling, movement, and securing of heavy loads using various types of equipment such as cranes, hoists, and slings. The progression in this field typically follows a path from Rigger Level 1 to Rigger Level 4, with each stage involving increasingly complex tasks and responsibilities.Rigger Level 1: Starting the JourneyA Rigger Level 1 is often an entry-level position where individuals learn the basics of rigging. This stage focuses on simple, repetitive tasks, such as attaching rigging equipment, selecting appropriate rigging methods, and ensuring that all rigging setups are secure. At this level, the rigger works under supervision and deals with known load weights and configurations. The primary skills developed include inspecting rigging before use, identifying and selecting rigging components, and recognizing potential hazards in the rigging process. This stage is critical for building a solid foundation in rigging practices and safety standards.Rigger Level 4: Advancing in the FieldAs a rigger gains experience and confidence, they can progress to Rigger Level 4. This level allows for more independence and involves more complex rigging tasks, such as calculating load weights, determining the center of gravity, and selecting appropriate rigging components for specific jobs. A Rigger Level 4 can perform these tasks without supervision and is expected to have a deep understanding of load dynamics, hoisting equipment, and the various factors that can affect the stability and safety of a lift. This level of certification also includes performing pre-use inspections of rigging equipment and identifying lift points, which are crucial for ensuring safe and efficient operations.Career Opportunities and ProgressionRiggers have opportunities across various industries, including construction, oil and gas, manufacturing, shipping, and even the entertainment industry. The skills developed as a rigger are highly transferable, allowing individuals to move between different sectors. For example, construction riggers may transition into crane operation or specialize in specific rigging tasks like heavy lifting in offshore oil rigs.The progression from Rigger Level 1 to Level 4 not only increases job responsibilities but also opens up avenues for higher wages and specialized roles. Certification, often provided by recognized bodies like the API and National Commission for the Certification of Crane Operators (NCCCO), is crucial in advancing a rigger's career, as it demonstrates competence and adherence to safety standards. With experience and further training, riggers can advance to supervisory roles or specialize in more technical areas of rigging, such as crane operation or lift planning.In summary, a career as a rigger offers a structured path of progression with opportunities for specialization and advancement in various industries. The key to success in this field is continuous learning, hands-on experience, and a commitment to safety and precision in every task. For more detailed information on becoming a certified rigger and the specific tasks involved at each certification level, you can explore resources like the [NCCCO](https://www.nccco.org/) and specialized training providers like [Elite Offshore](https://eliteoffshore.in).

More detailsPublished - Sat, 31 Aug 2024

Created by - Elite Offshore

Role of Safety Signs in Promoting a Safer Work Environment

Safety signs play an important role in maintaining a safe and organized work environment. They communicate potential hazards and risks to employees and visitors and alert individuals to dangers such as slippery floors, electrical hazards, chemical exposures, or restricted areas. They serve as constant reminders about safe practices and procedures. Safety signs provide clear instructions on what actions to take to maintain safety. For example, they may indicate the location of emergency exits, first aid kits, fire extinguishers, or safety equipment. They contribute to creating a safer environment for everyone.During any emergencies, safety signs provide critical information quickly. They guide individuals to safety exits and emergency equipment, ensuring a prompt and organized response to crises like fires, chemical spills, or medical emergencies. In diverse workplaces, safety signs use universally recognized symbols and icons to overcome language barriers. This ensures that safety information is understood by all employees, regardless of their native language.Safety signs may be categorised as below:1. Warning signs 2. Prohibition signs 3. Emergency signs4. Hazard signs5. Road safety signs 6. Fire Safety Signs7. Construction safety signs8. Safety awareness signs9. Commercial floor signs10. Braille signsThus Safety signs play a crucial role and are integral to promoting a safety-conscious culture, preventing accidents, complying with regulations, and ensuring everyone in the workplace understands and follows essential safety protocols. These topics are adequately covered during various safety training programs e.g. Workplace Safety.

More detailsPublished - Thu, 18 Jul 2024

Created by - Elite Offshore

Importance of Magnetic Compass Adjustment Aboard Ships

Importance of Magnetic Compass Adjustment Aboard ShipsNavigating the vast and unpredictable oceans has been a hallmark of human exploration and commerce for centuries. From ancient seafarers guided by the stars to modern maritime professionals relying on sophisticated technology, one instrument has stood the test of time as a fundamental tool of navigation: the magnetic compass. Despite advancements in electronic navigation systems like GPS, the magnetic compass remains indispensable, serving as a reliable backup and essential tool for maintaining course and ensuring the safety of ships at sea.The Magnetic Compass as the Foundation of navigationThe magnetic compass is a simple yet ingenious device that aligns itself with the Earth's magnetic field, indicating the direction of magnetic north. This fundamental principle has guided sailors and explorers across oceans and continents, providing a constant reference point even in the absence of visible landmarks or celestial cues.On modern ships, the magnetic compass continues to play a crucial role alongside Gyro Compass which is an electronic navigation aid. Its importance lies not only in its simplicity and reliability but also in its regulatory requirement aboard all vessels, ensuring compliance with international maritime laws and safety standards.Understanding Magnetic Compass AdjustmentTo appreciate the significance of magnetic compass adjustment, it is essential to understand the factors that affect its accuracy. The Earth's magnetic field is not uniform, and onboard magnetic influences from the ship's structure and equipment can cause deviations, known as compass errors. These errors can lead to inaccuracies in directional readings, potentially jeopardizing safe navigation. The two main errors experienced are known as Deviation and Variation.Magnetic compass adjustment, also known as compass swinging or compass compensation, involves techniques to minimize these errors and ensure the compass provides accurate readings. This adjustment process is critical for several reasons:1. Safety and ReliabilityThe primary reason for magnetic compass adjustment is to enhance the safety and reliability of navigation at sea. Imagine a scenario where electronic navigation systems fail due to a technical glitch or a cyber-attack. In such situations, the magnetic compass becomes the primary means of determining the ship's heading. Ensuring its accuracy through regular adjustment is crucial for maintaining course and avoiding navigational hazards.2. Compliance with International RegulationsInternational maritime regulations, including those established by the International Maritime Organization (IMO), mandate that all vessels must have properly adjusted and calibrated magnetic compasses. These regulations are designed to ensure uniform standards of safety and operational competence across the global maritime industry.3. Reducing Compass Deviation and VariationCompass deviation refers to the discrepancies between the magnetic compass readings and the actual direction of true north. This deviation can be caused by various factors, such as the presence of ferrous metals, electrical equipment, and magnetic anomalies aboard the ship. Without proper adjustment, these deviations can lead to navigational errors, potentially resulting in course deviations, collisions, or groundings.Through meticulous adjustment techniques, compass adjusters mitigate these deviations by compensating for onboard magnetic influences. This process involves carefully measuring and calculating the effects of deviation on the compass readings and applying corrections to ensure accuracy.The Variation is the difference between the magnetic north your compass points to and true north. – This difference is caused by the Earth's magnetic field. This error is fixed for a particular location on earth and varies with time. This error is mentioned on the chart and need so be applied while making compass adjustments.4. Enhancing Navigation EfficiencyIn today's maritime industry, where efficiency and precision are paramount, accurately adjusted magnetic compasses contribute to efficient navigation operations. They provide reliable directional information that complements electronic navigation systems, offering redundancy in case of system failures or emergencies.Moreover, for vessels navigating in regions with limited GPS coverage or where electronic navigation aids are unreliable, a well-adjusted magnetic compass remains an invaluable asset. It serves as a dependable backup, ensuring continuous navigation capability regardless of external conditions.5. Professional Competence and Skill DevelopmentFor maritime professionals, proficiency in magnetic compass adjustment is important and crucial. It demonstrates a thorough understanding of navigational principles and the ability to apply them effectively in real-world scenarios.Courses and training programs, such as those offered by institutions like Elite Offshore, play a pivotal role in equipping compass adjusters with the knowledge and practical skills needed to perform their duties competently. These programs cover a wide range of topics, including the theory of magnetism, adjustment techniques, regulatory requirements, and practical hands-on sessions using specialized equipment.The importance of magnetic compass adjustment aboard ships cannot be overstated. It serves as a foundational element of maritime navigation, ensuring the safety, compliance, and efficiency of vessels navigating the world's oceans. Through rigorous training, adherence to international regulations, and meticulous adjustment techniques, maritime professionals uphold the standards of navigational excellence that have defined the industry for centuries.

More detailsPublished - Mon, 08 Jul 2024

Search

Popular categories

OSHA & Industrial Safety Courses

11Liberia Approved Rig Courses

4Marine and Offshore

3IADC Approved - E learning

1Port & Marine Courses

1Offshore Oil and Gas Rig Courses

1Latest blogs

Maa Durga – A Divine Guide to Safety at Home and in Industries

Thu, 14 Aug 2025

The Alarming Decline in Safety and Skill Training: A Risk We Can't Ignore

Fri, 27 Dec 2024

Telescopic Handlers (Telehandlers) vs Rough Terrain Forklifts

Thu, 31 Oct 2024

Write a public review